✔ Production downtime risks

✔ Limited trainer availability

✅ 90% faster training cycles reduced from 5 weeks to 1 day

✅ Zero disruption to live production

✅ Scalable, repeatable hands-on practice

The Challenge: Specialised Training only available outside of Ireland

Boston Scientific faced major constraints in training technicians on its mission-critical chemical process. Traditional lab-based methods created unsustainable bottlenecks. Only a few trainees could be accommodated at once. The high costs of accessing lab times, materials, and instructors’ hours added up. Training took place outside of Ireland, so every time someone had to be upskilled, they had to fly out to another site. They needed a way to train employees efficiently without sacrificing quality or slowing down operations.

The Solution

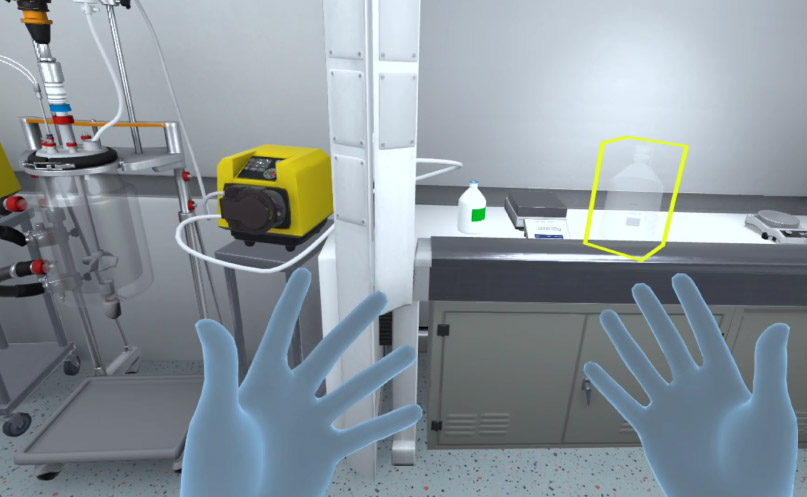

Mersus developerd a fully immersive VR Training program using Avatar Academy. This replicated the lab environment in a risk-free virtualised space. Key features included:

- True-to-life process simulations – Every step mirrored real-world procedures.

- Modular learning – Trainees could follow structured lessons or jump to specific skills.

- Voice & text guidance – Instant feedback reinforced best practices.

- Repeatable practice – No material waste or scheduling conflicts.

Using the TIBA Avatar Academy, in the space of a day you can run six or seven times the same training process that previously would take four or five weeks! Mersus Technologies’ virtual reality solution has revolutionised the way we train our staff, and we couldn’t be happier with the results.Tom Quilty, Process Development Fellow, Boston Scientific

AWARD-Winning Innovation

Recognised as the Best Training & Development Program at the 2022 National Manufacturing & Supply Chain Awards, this VR solution proves that immersive learning isn’t just the future—it’s delivering results today.