Inconsistent production rates and high defect rates.

✅ 75% faster training (12 days → 3 days)

✅ 50% reduction in defect rates

✅ Improved trainee confidence

The Challenge

A leading medical device manufacturer encountered significant challenges when training new employees on highly specialised tasks. These difficulties stemmed from limited access to the required machinery, a shortage of skilled trainers available for instruction, and the inherent complexity of the precision work, which often required being performed under magnification.

Consequently, traditional training methods proved extremely time-consuming, requiring over twelve days per employee to complete. Furthermore, they were highly resource-intensive, demanding a dedicated one-to-one trainer-to-trainee ratio. This approach also resulted in inconsistent training outcomes, ultimately leading to variable production speeds and a higher rate of defects on the manufacturing line.

Introducing new employees on the shop floor is challenging. Many tasks require training under magnification, previously demanding a dedicated trainer for each trainee.Company Executive, Medical Device Manufacturing

The Solution

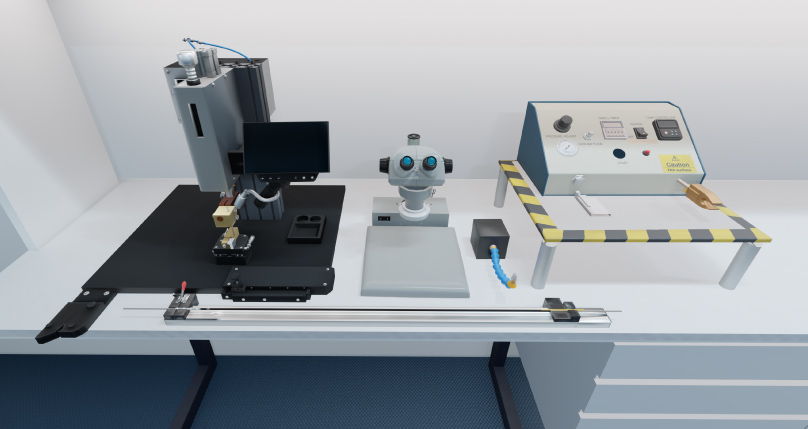

To address these training challenges, we developed a custom VR training program hosted on our immersive platform, designed to accurately simulate real-world manufacturing environments. The solution featured adaptable training modules covering core workflows, multiple learning modes (Education, Practice, and Examination) for comprehensive skill reinforcement, and real-time performance analytics to meticulously track trainee progress.

Crucially, the VR simulations enabled employees to safely practice complex tasks without risk, build essential muscle memory and equipment familiarity before engaging in live operations, and significantly reduce their dependency on in-person trainers.

This VR training builds muscle memory for trainees. It raises awareness of materials and equipment terminology.Lean Engineer, Medical Device Manufacturing

Measurable Outcomes

After implementation, the manufacturer achieved:

- 75% faster onboarding (12 days → 3 days)

- 50% fewer defects in post-training production

- Consistent production output, meeting customer demand without delays

The success extended beyond efficiency—the company also highlighted cost savings and sustainability benefits from reduced material waste and trainer hours.

VR training takes away the one-size-fits-all approach…we’re saving money, improving efficiency, and giving more people the opportunity to train in a way that works best for them.VP, Medical Device Manufacturing